- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

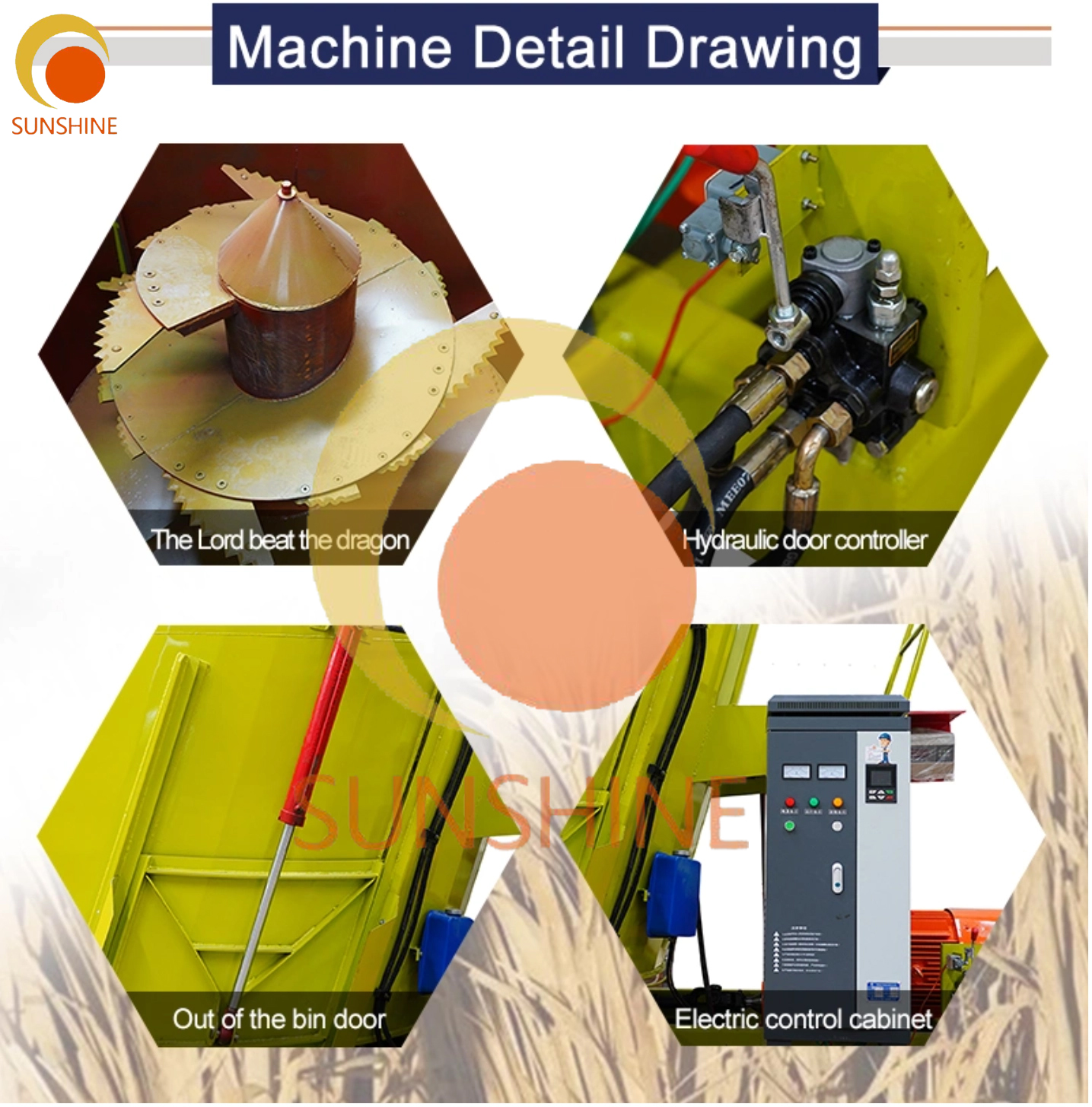

SUNSHINE Industrial Farm Vertical TMR Feed Mixer

Machine Application

A complete ration feed mixer thoroughly mixes roughage, concentrate, minerals, vitamins, and other additives to provide sufficient nutrition to meet the needs of dairy cows. Advantages: It provides sufficient nutrition to meet the nutritional needs of dairy cows, increasing milk production; increases dry matter intake, eliminates cows' pickyness about certain feeds, and helps minimize feed formulation costs; significantly reduces unexpected trace element and vitamin deficiencies or poisoning; reduces the incidence of dairy cow diseases; improves dairy cow reproduction rates; significantly saves labor time, and improves economic benefits.

Precautions Before and After Production:

1. Check that all machine components are intact, fasteners are properly tightened, the transmission belt or chain is correctly connected, the lubrication holes are greased, the distribution box is correctly wired, and safety guards are in place. Once everything is confirmed, power on the machine for a test run, idling for 5 to 10 minutes.

2. After idling, if the equipment is operating normally, you can start production. Use a belt conveyor or loader to add the mixed feed to the silo and mix it evenly. Ensure the feed is evenly distributed and avoid overloading the machine due to excessive feeding. This ensures the quality of the mixed feed while preventing malfunctions.

3. If any equipment malfunctions during production, immediately disconnect the power supply and have professional maintenance personnel perform maintenance and troubleshooting. Never operate the machine while it is faulty, as this may cause unnecessary losses.

4. The mixed feed is discharged through the hydraulic system control to open the discharge port. The material should not be too wet or slippery to prevent clogging the discharge port. Please schedule the machine start-up according to your production shift and feeding requirements.

5. Clean the machine and relubricate it after use. Equipment used outdoors should be protected from rain, snow, and moisture after it is no longer in use. In particular, electrical components should be protected from water and moisture.

Common Problems and the Solutions

1.Question: Feed outlet is blocked

Reason:The working material has high humidity

Solution: Choose drier materials

2.Question:Uneven mixing

Reason:Stirring time is too short

Solution: Increase mixing time

3.Question:The discharge port cannot be opened

Reason: Hydraulic system failure

Solution: Shut down and inspect hydraulic systems and pipelines

4.Question: The dragon stirrer does not move

Reason:Powertrain failure

Solution: Stop and check the motor wiring and transmission system

5.Question: The machine makes unusual noises

Reason: Hard materials are put into the mixing bin, the hydraulic pipeline is damaged, and the bolts are loose.

Solution: Check for foreign objects in the material compartment, repair hydraulic system pipelines, tighten nuts or replace bolts