- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Tel: +86 18103710497

Email : admin@feedsunshine.com

Whatsapp: +86 18103710497

Address: No. 1, sunshine Avenue, Ji- cheng Industrial Park, Xinxiang City.

| Power: | |

|---|---|

| Capacity: | |

| Weight: | |

| Warranty:: | |

| SKU: | |

| Availability: | |

| Quantity: | |

ZC560

SUNSHINE

Product Description

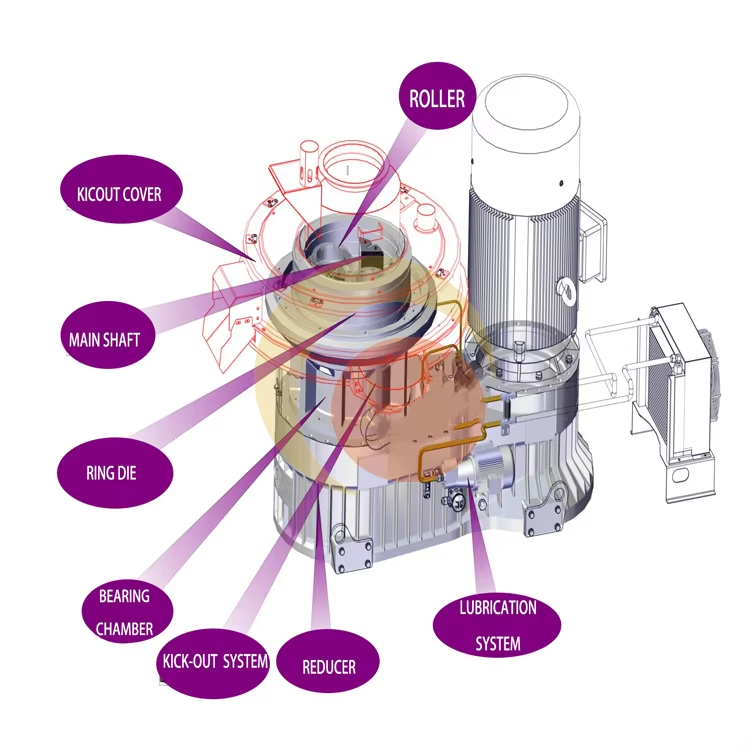

SUNSHINE Ring Die Biomass Pellet Machine Introduction

Biomass pellet machine is equipment for recycling wood chips, corn stover, wood shavings, bark and waste from wood mills.It adopts high-precision gear transmission mechanism and is equipped with a forced feeding device to ensure the smooth operation of the machine.The formed pellet fuel has the characteristics of high combustion value, high density, green environmental protection, and convenient transportation. The volume of the formed pellets is 1/8 of the raw material volume, the density is 0.8-1.5, and the calorific value can reach 3400~6000 kcal. Biomass pellet machine is a new type of bioenergy equipment, which is a good choice for turning waste into treasure.

Advantage:

1. Vertical feeding, no arch of raw materials, easy to dissipate heat in the granulation chamber.

2. Double-layer ring die, which can be used both up and down to reduce production costs.

3. The mold is fixed, the drum rotates, the pressure is high, the material is centrifuged, and the distribution is even, which improves the production capacity and ensures the hardness and density of the particles.

4. It has an automatic lubrication system, which is convenient for maintenance, reduces costs and prolongs the service life of the equipment.

5. 24 hours of continuous operation, saving labor.

1. Biomass pellet machine is a kind of biomass energy pretreatment equipment. It mainly uses agricultural and forestry processing waste such as wood chips, straw, rice husks, bark and other biomass as raw materials, and solidifies them into high-density pellet fuel through pretreatment and processing.

2.Biomass pellet machines are divided into flat-die biomass pellet machines and ring-die biomass pellet machines. Characteristics of biofuel:

The formed pellet fuel has a large specific gravity, small size, combustion resistance, and is easy to store and transport. The density after molding is 1.1-1.5.

The calorific value can reach 3400~4800 kcal. It is a solid fuel with high volatile content and low sulfur content.

3.Uses of biomass fuel The molded pellet fuel is a new type of bioenergy that can Instead of firewood, raw coal, fuel oil, liquefied gas, etc.

Wood Pellet Machine Working Principle

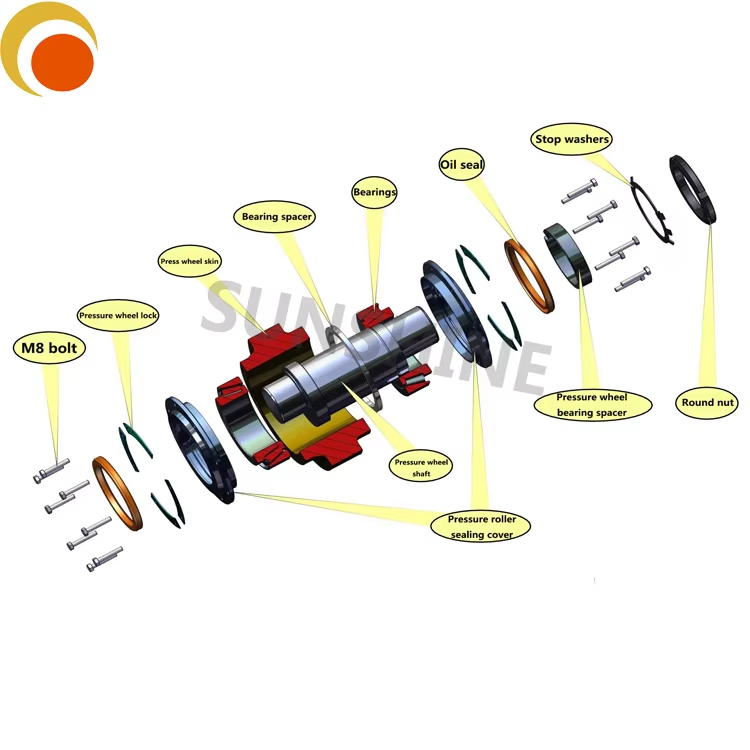

The sawdust pellet machine is driven by a belt and a worm gear in two stages, with stable rotation and low noise. It is a granulator that is loved by consumers. The sawdust pellet motor drives the main shaft through the reducer, and the main shaft drives the pressing wheel. The pressure wheel revolves around the main shaft and rotates around the grinding disc. When biomass and pellets are processed, the raw materials are fed into the feeding chamber of the flat die machine. Under the combined action of the distributor and the scraper, the material layer is continuously rolled on the flat die by the driven spindle roller, and the material is extruded into the die. Inside, the material forms holes in the mold and other processes, and after a certain period of time, it is extruded in a cylindrical form, and the rotating knife cuts the material to form particles, and the sweeping plate composed of particles will be sent out.

Product Paramenters

| Model | Capacity | Power | Size | Weight |

| ZC450 | 0.5-0.6TPH | 55kw | 1800*1000*1780mm | 3.5T |

| ZC470 | 0.6-1TPH | 75kw | 1800*1000*1780mm | 4T |

| ZC560 | 1-1.2TPH | 90kw | 2350*1500*1850mm | 5.6T |

| ZC580 | 1.5-1.8TPH | 110kw | 2450*1600*1850mm | 5.8T |

| ZC650 | 1.8-2TPH | 132kw | 2550*1700*1850mm | 6.5T |

| ZC700 | 2.5-2.8TPH | 160kw | 2800*1800*1950mm | 7.5T |

| ZC750 | 2.8-3TPH | 185kw | 2900*1850*2000mm | 7.8T |

| ZC850 | 3-3.5TPH | 250kw | 3200*2200*2500mm | 11T |

| ZC880 | 5TPH | 315kw | 3400*2500*2500mm | 16T |

| Remark:Feed screw conveyor motor power 4.5kw | ||||

Wood Pellet machine Key Performance

The sawdust pellet machine is driven by a belt and a worm gear in two stages, with stable rotation and low noise. It is a granulator that is loved by consumers. The sawdust pellet motor drives the main shaft through the reducer, and the main shaft drives the pressing wheel. The pressure wheel revolves around the main shaft and rotates around the grinding disc. When biomass and pellets are processed, the raw materials are fed into the feeding chamber of the flat die machine. Under the combined action of the distributor and the scraper, the material layer is continuously rolled on the flat die by the driven spindle roller, and the material is extruded into the die. Inside, the material forms holes in the mold and other processes, and after a certain period of time, it is extruded in a cylindrical form, and the rotating knife cuts the material to form particles, and the sweeping plate composed of particles will be sent out.

Vertical Ring Die Granulator

1. Gearbox: It adopts high-precision gear transmission and is equipped with an automatic hydraulic circulating oil system, which ensures the service life of the gearbox and the working stability of the pellet mill.

2. Vertical motor: It works vertically, and its outstanding feature is that the mounting hole is centered on the output shaft, and the circumference is equidistantly distributed, which makes the machine run with greater power and stability.

3. Fan system: It is located on the side of the working bin of the pellet machine, and its working time can be freely controlled. The main function is to help the working bin of the pellet machine to remove dust and discharge steam.

4. Workpiece part: The mold and pressure roller are made of 20CrMnTi alloy steel, and the hardness can reach above 52 after heat treatment, which not only ensures the granulation effect, but also enhances the service life

5. The working mode is extruded from the inside out, the centrifugal force and the extrusion force are combined to increase the output while ensuring the hardness and density of the particles

6. Adopt the unique design of 4-8 pressing rollers to increase the extrusion frequency and increase the output

450 is 3 pressure rolls 550 is 4 pressure rolls 800 is 6 pressure rolls 1000 is 8 pressure rolls

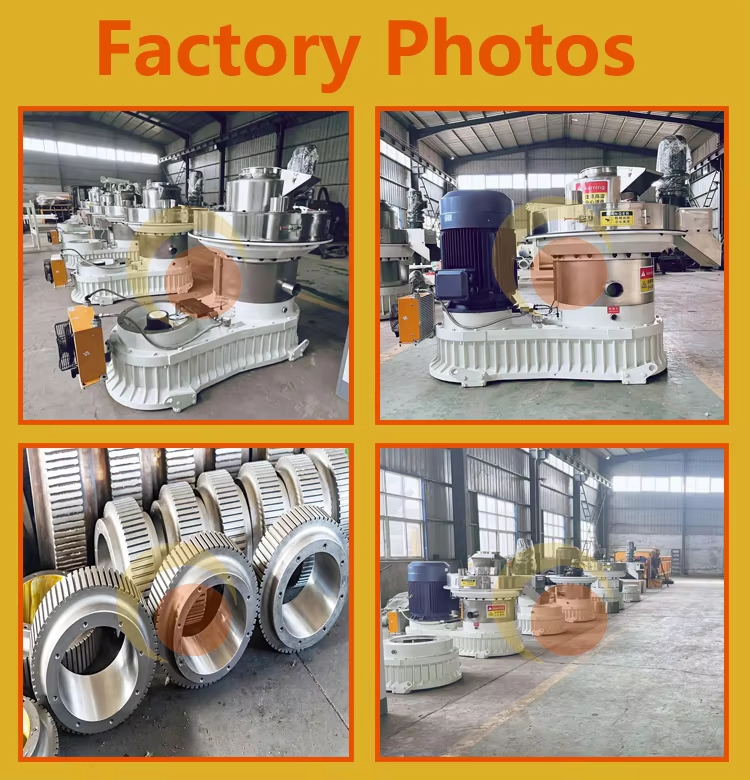

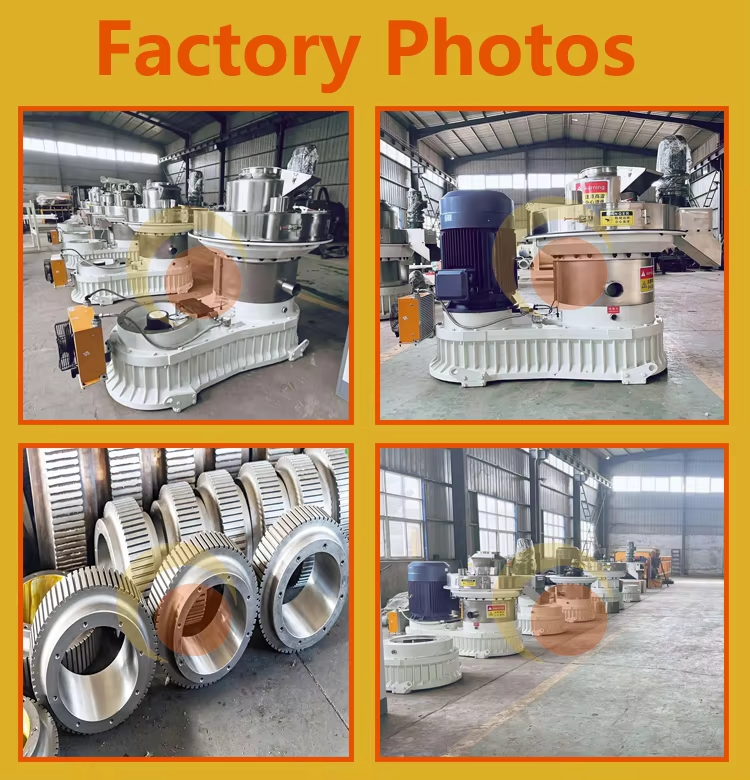

Exhibition Photos

Product Real Shot

Product Packaging

Company Profile

Henan Sunshine Industry Co.,Ltd is a manufacturing enterprise,integrating scientific research,production and marketing.The mainproducts are feed pellet machine and feed pellet production line,fish feed extruder machine .Our company regards the product quality as the life of our exterprise.We have ISO,CE,SGS certificate.Our pellet machines are the recommended products in China machinery industry.,At the same time, we are also introducing international advanced technologies and processes, coupled with a comprehensive and complete modern production operation management system. High-quality requirements,excellence in manufacturing, and long-term and extensive technical experience have continuously improved the quality of our company's products and services. All products and projects can run effectively, stably and reliably,Win a great reputation in domestic and abroad.We have exported more than 100countries like USA,Ecuador,Peru, Germany,Mexico, Canada, Spain, Tanzania,Saudi Arabia,Russia,Singapore, Thailand, India etc.Quality is life,Efficiency is guarantee,service is foundation,Innovate is our motive power,reputation is premise,Brand is target.

Biomass Pellet Machine

Packaging Inner packaging: we can use plastic packaging if customer needs

Outer packaging: usually a wooden case or container

We can also pack the machines according to customers' needs.

Delivery method: by sea

Delivery time: We respect the contract and will deliver on time as agreed on custom orders. For regular products, we have stock for immediate delivery.

![]() Technical Service:

Technical Service:

1.Design for production line flow and equipment layout freely according to the site.

2.Supply the foundation drawing of equipment and drawing of parts made by buyer

3.Supply the technical parameters of peripheral equipment.

4.During the operation,we can offer the technology service freely if the user needs to adjust the layout and application.

5.During the operation, we only collect the cost if the user willing to upgrade the equipment when we have the advantage technology.

![]() After-sales service

After-sales service

1. During installation and debugging, send technicians to the site to guide installation and debugging.

2. During the installation and commissioning process, we provide training services

3. The quality assurance date is one year after commissioning.

4. If the equipment fails due to improper handling by the user, we will be responsible for the maintenance and charge the corresponding fee.

5. We provide components with favorable price, lasting maintenance. After the quality assurance period, if the equipment needs to be repaired, we only charge the cost price.